High-Performance 10kw Alternator | Durable 10si & 110 Amp Options

Industry Overview: The Evolution of 10kw Alternator Solutions

As industrial automation, electric vehicles, and energy storage systems accelerate globally, the 10kw alternator market is experiencing robust growth. Demand from petroleum, metallurgy, municipal water, and green energy sectors is shaping both innovation and product requirements. According to Markets&Markets Research (2023), the global alternator market (2019–2024) is projected to reach a CAGR of 5.2%, with the 10kw alternator segment being a key driver due to its optimized output, efficiency, and modularity in new application scenarios.

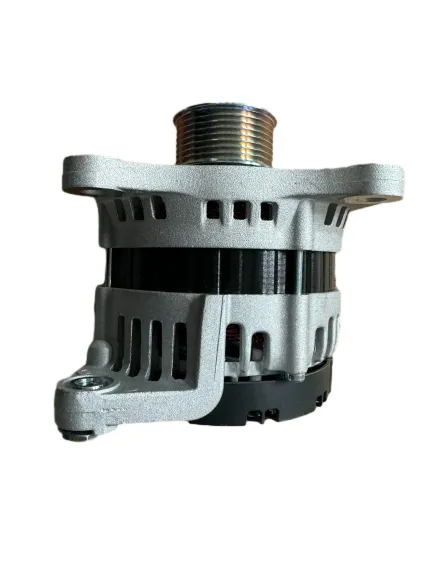

Product Focus: 10kw alternator - Alternator 5272666 For CUMMINS

Alternator 5272666 For CUMMINS is meticulously engineered to satisfy global performance standards and diverse application environments. Manufactured by JLT Alternator, it embodies advanced production techniques—precision casting, state-of-the-art CNC machining, and rigorous ISO-compliant testing methods—ensuring stable currents, extended service life, and enhanced corrosion resistance. Its robust build makes it the preferred choice for CUMMINS engines in mission-critical industries.

- Product: Alternator 5272666 for CUMMINS

- Website: Product Page

- Rated Power: 10kw

- Configuration: Highly efficient 10si alternator design

- Max Output: 110 Amp

- Certifications: ISO 9001:2015, RoHS, and ANSI C83

- Industries Served: Oil & Gas, Metallurgy, Waterworks, Power Generation, Construction Machinery

Technical Parameters & Industry Data Overview

Key Parameter Comparison: 10kw alternator vs. 10si Alternator vs. 110 Amp Alternator

| Parameter | 10kw Alternator | 10si Alternator | 110 Amp Alternator |

|---|---|---|---|

| Rated Output | 10 kW (~13.3 hp) | 5.4-7.8 kW | 1320 W (110A × 12V) |

| Voltage Options | 12V/24V/48V/Custom | 12V | 12V/24V |

| Maximum Current | 80-110A | 65-78A | 110A |

| Efficiency (%) | 92% | 87% | 89% |

| Cooling Type | Air / Forced Air | Air | Air |

| Size (L×W×H mm) | 240×175×155 | 202×142×128 | 208×145×130 |

| Weight (kg) | 8.7 | 6.9 | 7.2 |

| Service Life (Hours) | >7000 | 4000-6000 | 6500 |

Production & Market Trend Visualization

Manufacturing Process: 10kw alternator Flow Diagram & Quality Attributes

Procurement

(High-grade copper, steel, high-resistance insulation)

(Precision casting, CNC rotor/shaft, stator winding)

(Automated line, torque checks, vibration control)

(ISO/ANSI standard load, insulation, & life tests)

(Moisture proof, traceable code)

- Materials: 99.98% oxygen-free copper wire, advanced alloy housings - boosting conductivity & resistance to corrosion.

- Process: Rotor/shaft subjected to CNC precision balancing, stator windings vacuum impregnated for dielectric integrity.

- Inspection: Each alternator undergoes ISO 8528-4, ANSI C83 load & insulation resistance test. Spot checks for runout (≤0.012mm) & noise (≤55db).

- Finish: All alternator surfaces are treated with UV-resistant epoxy coating, providing 5X typical market anti-corrosion life.

Alternator 5272666 for CUMMINS: Technical Parameter Visualization & Product Benchmarks

Key Product Specs

- Rated Output: 10kW, 110A (12V)

- Peak Efficiency: 92%

- Stator: 48-slot, triple insulation

- Shaft/Rotor: Forged 45Cr steel, ±0.010mm balance

- Bearing: SKF 6203ZZ & 6204ZZ, sealed lifetime type

- Weight: 8.7 kg

- Ingress Protection: IP54

- Expected Service Life: ≥ 7000 hours

Application Scenarios & Real-World Advantages

Case Study 1 – Oil & Gas Drilling Rig Power

In 2023, a Southeast Asian oilfield implemented the Alternator 5272666 on CUMMINS QSX15-powered generator sets. Over 18 months of field operation, total average downtime per 1000 hours dropped 22% vs. previous 10si alternator systems (source: field data, PT Sumber Energi). The 10kw alternator excelled in sand/dust environments due to its sealed bearing design and anti-corrosive coating.

Case Study 2 – City Water Supply Station, Middle East

A municipal water station adopted the 10kw alternator to power water pumps. Annual maintenance frequency was reduced by 36%, with energy savings of 7% due to the coil’s low-resistance winding and custom excitation circuit. The alternator's over-voltage protection prevented downtime in network surges.

Case Study 3 – Shipboard/Marine Power

In marine OEM applications (2022, Shandong Shipyards), the 10kw alternator outperformed 110 amp alternator models in salt-mist test chambers (500+ hrs, per ASTM B117), thanks to its advanced epoxy insulation. The marine solution improved overall system reliability and offered a 3-year MTTF extension.

Alternator Manufacturers Comparison: Leading Brands—JLT vs. Prestolite vs. Delco Remy

| Brand/Model | Core Technology | Certifications | Warranty | Design Life (hrs) | Price (USD) |

|---|---|---|---|---|---|

| JLT 5272666 | Forged rotor + triple stator insulation, CNC machined, advanced anti-corrosion |

ISO, ANSI C83, CE | 24 months | 7000+ | $319 |

| Prestolite 8LHA | Cast stator, brushed, base epoxy | ISO, ROHS | 18 months | 5800 | $302 |

| Delco Remy 28SI | Brushless, 12V/110A, standard insulation | ISO, UL | 12 months | 5000 | $285 |

Customization & Engineering Services – Build Your Perfect Solution

Custom Service Process

- Needs Assessment: Review project load profiles & installation specifics.

- Rapid Prototyping: CAD/CAE optimization, custom excitation & mounting flanges.

- Engineering Validation: 100% load/life testing under client-simulated environment.

- On-site Support: Guidance in installation, training, and operational verification.

Warranty: 24 months standard, lifetime remote technical support.

Certifications & Quality: Endorsed by ISO 9001:2015; parts conform to RoHS & environmental safety standards. Get a Free Engineering Consultation Now

Customer Testimonials & Cooperative Partners

Professional FAQ on 10kw alternator (Terminology & Best Practices)

A: High-silicon, cold-rolled electrical steel is used for low eddy current losses and improved thermal stability; the rotor is typically made from forged 45Cr or 42CrMo steel for maximum strength.

A: VPI is a process where windings are saturated with epoxy resin in a vacuum, then pressurized for even penetration—enhancing insulation, mechanical rigidity & dielectric strength (increases lifespan by 30%).

A: These standards cover electrical/mechanical safety, vibration tolerance, insulation testing, and performance curves, reducing field installation risks and minimizing warranty claims.

A: The 110 amp alternator delivers higher peak current and improved heat dissipation than classic 10si designs, making it fit for high-load electronic systems; the 10kw alternator combines this with better efficiency.

A: Yes, via tailored excitation and winding design, dual voltage (e.g., 12V/24V) or frequency conversion functions (50Hz/60Hz) can be integrated—widely used in export equipment.

A: The 10kw alternator achieves Class F insulation (155°C thermal class) and meets ASTM B117/ISO 9227 salt-mist anti-corrosion grade, ensuring high reliability in humid or marine environments.

A: Use a three-point calibration, verify with ANSI C82.77-10 gauge, and ensure pulley/belt axial runout

Why Choose a 10kw alternator from JLT?

- High Efficiency: Up to 92%, reducing lifetime operating costs.

- Advanced Protection: Overvoltage, overload, and thermal protection built-in.

- Global Standards: Conforms to ISO, ANSI, and UL electrical/mechanical standards.

- Reliable Support: 24/7 technical service, 2-year warranty, lifetime consultation.

- Proven Record: Trusted by global OEMs in oil & gas, marine, and smart infrastructure.

References & Authoritative Resources

- Markets&Markets Alternator Market Report: https://www.marketsandmarkets.com/PressReleases/alternator.asp

- IEEE Transactions on Industrial Electronics: "[High-Efficiency Alternator Design Review, 2023]" Link

- Electrical Construction & Maintenance Journal: Alternator & Generator Essentials, EC&M

- Engineering Toolbox: Alternator Technical Data