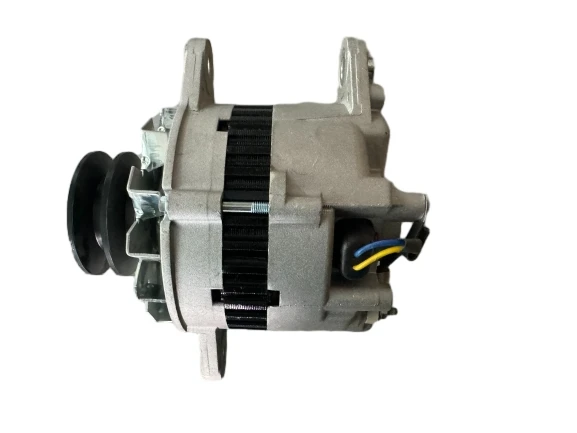

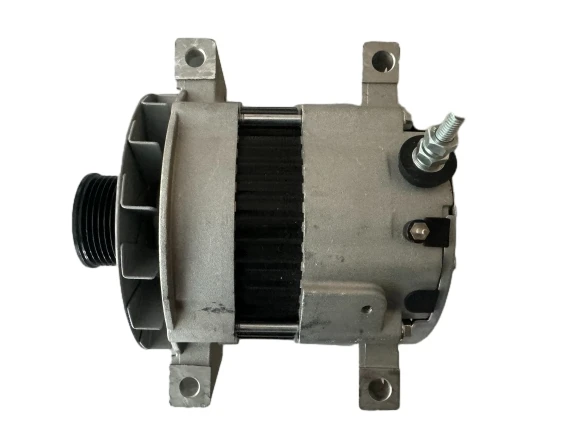

The working principle of an alternator is based on electromagnetic induction. As the engine runs, it drives a belt that spins the alternator's rotor at high speed. This rotor, essentially an electromagnet, rotates within a stationary set of copper windings called the stator. The movement of the magnetic field induces an electrical current in the stator windings. Since this current alternates in direction, a rectifier assembly converts it to the direct current required by the vehicle's electrical system. A sophisticated voltage regulator monitors and adjusts the output to maintain optimal charging voltage, typically between 13.5 and 14.5 volts for 12-volt systems, ensuring stable operation of all electrical components while preventing battery overcharge.

Modern alternators represent significant advancements over their predecessors. They are engineered to be more compact, efficient, and durable while producing higher outputs to meet the increasing electrical demands of contemporary vehicles. Many incorporate intelligent charging systems that communicate with the vehicle's computer to optimize performance based on driving conditions. Some high-efficiency designs even contribute to fuel economy by reducing parasitic losses on the engine.

The importance of a properly functioning alternator cannot be overstated. It powers everything from essential systems like ignition and fuel injection to comfort features such as air conditioning and infotainment. A failure in this component typically leads to complete vehicle shutdown once the battery is depleted. For this reason, modern alternators are built to withstand harsh operating conditions, with robust construction and advanced cooling systems ensuring reliable performance throughout the vehicle's lifespan.