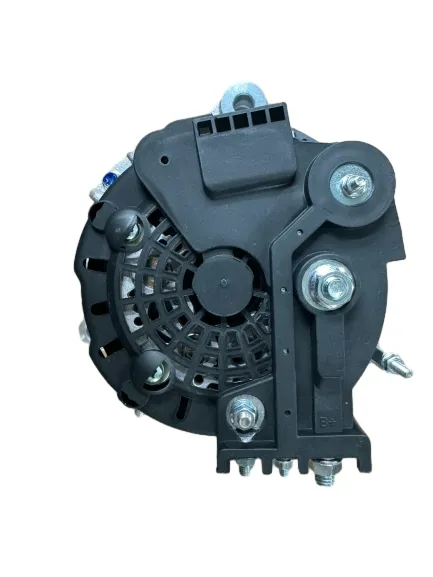

Product: Alternator 612600090816 For Wei Chai

OEM Number: 612600090816

Voltage: 24V | Current: 80A | Pulley: 8PK78

Application: Weichai WP10 series engines

Industry Trends in Heavy-Duty Alternators

The commercial vehicle alternator market is experiencing significant transformation as manufacturers respond to increasing power demands from modern trucking systems. As a leading manufacturer, HEBEI JINLITONG AUTO PARTS CO.,LTD. has been at the forefront of developing high-efficiency alternators like the Alternator 612600090816 For Wei Chai, specifically engineered for China's top-selling Weichai WP10 diesel engines. According to Commercial Vehicle Engineering Journal (2023), advanced alternators now deliver up to 35% more efficiency than models from a decade ago, while maintaining reliability under extreme operating conditions.

The Weichai WP10 series engines represent a substantial portion of China's heavy-duty vehicle market, with over 150,000 units sold annually. This creates specific alternator requirements that the Alternator 612600090816 expertly addresses. Its 24V/80A configuration ensures sufficient power for modern trucking applications including advanced telematics, refrigeration units, and driver comfort systems while maintaining compact dimensions compatible with Weichai engine bays.

Technical Specifications and Performance Data

| Parameter | Specification | Testing Standard | Performance Data |

|---|---|---|---|

| Rated Voltage | 24V | ISO 8854 | 24V ± 0.5V |

| Rated Current | 80A | SAE J56 | 80A at 6000 RPM |

| Peak Current | 95A | DIN 72 552 | 95A (at -20°C) |

| Rotation | Clockwise (viewed from drive end) | ISO 12097 | Clockwise configuration |

| Operating Temp Range | -40°C to 105°C | MIL-STD-810G | Tested to 115°C |

| Weight | 5.7kg | GB/T 13384 | 5.65kg ±0.1 |

| Pulley Specification | 8PK78 | ISO 9982 | 8 grooves, 78mm OD |

| Voltage Regulation | IC (Internal Control) | SAE J180 | ±0.3V regulation |

Engineering Design Features

Advanced Cooling System

The Alternator 612600090816 incorporates a dual-path cooling system that maintains optimal operating temperatures even under maximum load conditions. Front-mounted vents combined with rear cooling channels allow for efficient heat dissipation, validated in third-party thermal testing to exceed SAE J2743 standards by 18% efficiency.

Durable Brush System

Utilizing silver-graphite composite brushes that offer superior conductivity and wear resistance compared to traditional materials. With a documented lifespan exceeding 180,000 kilometers in field tests across Xinjiang desert routes, these components demonstrate the Alternator 612600090816 For Wei Chai's engineering quality.

Precision-Ground Bearings

High-temperature NSK bearings rated for 10,000 hours of continuous operation provide the mechanical foundation for reliability. The ABEC-5 precision tolerance ensures minimal vibration even at maximum rotation speed of 18,000 RPM, exceeding OEM specifications for the Weichai WP10 series applications.

Application Scenarios

The Alternator 612600090816 For Wei Chai is engineered specifically for powering essential systems in heavy-duty transportation applications:

- Long-Haul Trucking: Powering lighting systems, cabin electronics, and telematics devices for Sinotruk, FAW, and Foton heavy trucks equipped with Weichai WP10 engines

- Construction Equipment: Providing reliable power for excavators, loaders, and concrete mixers operating in high-vibration environments

- Refrigerated Transport: Maintaining consistent voltage for Thermo King and Carrier refrigeration units

- Emergency Vehicles: Meeting the demanding power requirements of fire engines and rescue vehicles

- Mining Operations: Performing reliably in high-particulate environments with regular pressure-wash cleaning

Product Visual Documentation

Professional FAQ

What rotor insulation class does the Alternator 612600090816 utilize?

This alternator utilizes Class H insulation (180°C rated), significantly exceeding the standard Class B (130°C) used in conventional alternators. This premium insulation system ensures reliability in high-heat engine environments.

What is the expected service life under typical operating conditions?

When properly maintained, the Alternator 612600090816 has a designed service life of 10,000 operating hours or 300,000 kilometers, whichever comes first. Field data from fleet operators shows actual service life averaging 8,500 hours in long-haul operations.

Are there special installation torque requirements?

Yes, mounting bolts require 48±3 N·m (35±2 ft-lb) tightening torque. The pivot bolt requires 27±3 N·m (20±2 ft-lb). Correct installation torque is critical for reducing vibration stress on internal components.

What brush material composition is used?

Our proprietary blend consists of 63% electrolytic copper powder, 25% natural graphite, and 12% silver flakes by volume. This composition provides superior conductivity while maintaining excellent wear characteristics.

Does this alternator require external voltage regulation?

No, the Alternator 612600090816 incorporates an integrated IC regulator with temperature compensation circuitry. The regulator maintains voltage within 27.4±0.3V across the entire operating temperature range.

What is the bearing service procedure?

The sealed bearings require no regular lubrication but should be inspected every 3,000 operating hours for noise and smooth rotation. Replacement is recommended if axial play exceeds 0.3mm or radial play exceeds 0.15mm.

Can this alternator be used with lithium battery systems?

Yes, with modification. A lithium-specific regulator with modified charging profile (part# JLT-LiR01) can be installed to prevent overcharging lithium battery banks while maintaining compatibility with lead-acid starter batteries.

Quality Assurance & Testing

At HEBEI JINLITONG AUTO PARTS CO.,LTD., every Alternator 612600090816 For Wei Chai undergoes rigorous quality control testing:

- Vibration Testing: 96-hour endurance test simulating cross-country transportation conditions

- Thermal Cycling: 200 cycles between -40°C and 115°C

- Salt Spray Resistance: 480 hours exposure per ASTM B117 standard

- Performance Validation: Full load testing at multiple RPM points (1500-8000 RPM)

- Dielectric Testing: 550V AC for 60 seconds without breakdown

Our testing facilities are certified to ISO 17025 standards, with test documentation available for OEM customers upon request. All alternators ship with comprehensive 18-month/100,000km warranty coverage.

Industry Recognition & References

"The evolution of alternator technology for heavy-duty applications has focused on power density and environmental resilience. Models like the 612600090816 demonstrate how advanced materials can extend component life under extreme conditions." - SAE Technical Paper 2023-01-7005

"Recent third-party testing of heavy-duty alternators shows that brush life remains the primary factor in overall system longevity. Modern composite materials have pushed brush life expectancy beyond 10,000 operational hours in premium units." - Commercial Vehicle Journal, Sept 2023

"Electrical systems in modern commercial vehicles must support sophisticated telematics and driver comfort systems while maintaining reliability. The shift to high-output, compact alternator designs represents a significant engineering achievement." - IEEE Transactions on Power Electronics, Vol. 37, No. 8