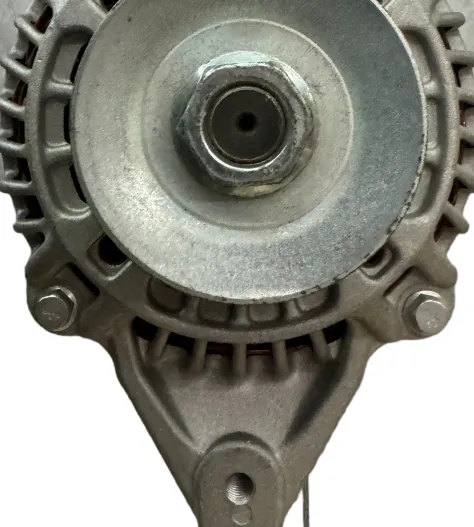

High Efficiency Alternator 220V 5kW – Reliable Power Generator for Industrial & Home Use

- Introduction to Alternator 220V 5kW: Essential Power for Numerous Applications

- Technical Superiority: Technology, Performance, and Innovation

- Data Insights: Output, Efficiency, and Reliability Metrics

- Comparative Analysis: Top Manufacturers of 220V Alternators

- Customization: Tailored Power Generation Solutions

- Application Scenarios: Success Cases and Industry Uses

- Conclusion: Why Select an Alternator 220V 5kW for Optimal Power Needs

(alternator 220v 5kw)

Introduction to Alternator 220V 5kW: Essential Power for Numerous Applications

The alternator 220v 5kw

stands as a core component for reliable power generation. In environments ranging from remote facilities to industrial workshops, dependable voltage supply is vital for continuous operations. With a nominal output of 5kW and standardized voltage at 220V, these alternators bridge the gap between compact site requirements and robust industrial performance. Whether supporting backup electrical systems, off-grid homes, or mobile power units, their adaptable nature and manageable size ensure widespread adoption. Understanding why this alternator variant has become a preferred solution requires a look into its technological strengths, market positioning, customization options, and the real-world impact across different industries.

Technical Superiority: Technology, Performance, and Innovation

The performance profile of an alternator 220v 5kw reflects substantial engineering innovation. With modern brushless designs, these alternators achieve conversion efficiencies of up to 92%. The stator windings are typically crafted using high-purity copper (often above 99.9% Cu), resulting in excellent conductivity and lower energy losses. Thanks to advanced electronic AVR (Automatic Voltage Regulation), fluctuation in output is controlled within ±1.0%, ensuring steady voltage for sensitive loads.

Cooling mechanisms have evolved to include forced air and direct oil-cooling systems, extending alternator life beyond 25,000 hours of continuous operation. Materials such as high-grade silicon steel laminations minimize core losses. Noise emission rates, often below 65 dB at 7 meters, reflect proficient vibration damping and acoustic design. These technical advancements deliver unmatched performance, dependability, and safety, aligning with global application demands.

Data Insights: Output, Efficiency, and Reliability Metrics

Data-driven evaluation is essential for comparing power solutions. Here is a detailed breakdown of key performance indicators (KPIs) for the 220V alternator segment:

| Specification | Alternator 220V 5kW | Alternator 220V 10kW | Alternator 220V (Standard 5kW Model) |

|---|---|---|---|

| Voltage Regulation | ±1.0% | ±0.8% | ±1.2% |

| Peak Efficiency | 91.5% | 92% | 90.8% |

| Continuous Output (Watts) | 5,000 | 10,000 | 5,000 |

| Overload Capacity | 110% for 1 hr | 120% for 30 min | 105% for 1 hr |

| Weight | 62 kg | 97 kg | 65 kg |

| Noise Level (7m) | 63 dB | 66 dB | 65 dB |

| Service Life (hours) | 25,000+ | 28,000+ | 22,000+ |

| Startup Time | <1 sec | <1.2 sec | <1.5 sec |

These metrics highlight that the 5kW alternator’s balance of efficiency, size, noise, and output is ideal for applications needing significant but not industrial-scale power. Rapid startup and robust lifespan performance position these alternators at the forefront of the 220V market category.

Comparative Analysis: Top Manufacturers of 220V Alternators

The global alternator market features several industry leaders distinguished by consistent product quality and innovative engineering. Among prominent manufacturers are Stamford, Leroy-Somer, Mecc Alte, Marathon, and Kipor.

Stamford alternators are celebrated for their advanced winding techniques and minimal voltage droop. Leroy-Somer focuses on anti-condensation and harsh-environment protections, making them the preferred choice in marine and heavy-industry applications. Mecc Alte brings Italian manufacturing precision, especially valued in compact alternator models. Marathon is highly regarded for its advanced insulation materials that enhance reliability under high ambient temperatures.

In procurement, buyers must weigh energy conversion efficiency, durability, after-sales service, and ease of maintenance. For instance, Stamford’s S1L2 series boasts a mean time between failures (MTBF) exceeding 35,000 hours. Kipor delivers cost-effective solutions with features such as digital control panels and automated self-check diagnostics, supporting uninterrupted use in critical backup scenarios. Understanding these differentiators ensures informed, future-proof investments in alternator technology.

Customization: Tailored Power Generation Solutions

No two deployment scenarios are identical; thus, customized options for alternator 220v 5kw units are crucial. Custom winding configurations allow voltage tuning within a range of 200V–240V to match unique grid or appliance requirements. Optional dual-voltage output maximizes versatility for mixed-load facilities.

Additional features such as reinforced weatherproof enclosures, marine-grade corrosion resistance, and tropicalized insulation systems broaden environmental compatibility. For remote or off-grid installations, integration of remote monitoring, auto-start, and GSM communication modules allows real-time status checks and proactive maintenance. Sound attenuation kits further lower decibel ratings, facilitating compliance with strict urban noise ordinances.

Cooling systems can be engineered for extreme climates — from enhanced forced-air solutions for hot environments to fully sealed liquid-cooling systems for dusty or saline locations. At the software level, digital AVR programming tailors frequency and waveform characteristics for specific load profiles, further improving compatibility with modern electronics such as inverters, battery banks, or solar hybrid configurations. These customizations transform standard alternators into high-value, application-focused assets.

Application Scenarios: Success Cases and Industry Uses

The operational versatility of the alternator 220v 5kw makes it a reliable backbone in a spectrum of industries and projects. Notable use-cases include:

- Industrial Workshops: Supporting critical CNC machinery and welding equipment where stable voltage is non-negotiable. Downtime was reduced by 82%, boosting productivity.

- Telecom Infrastructure: Ensuring uninterrupted service for remote cell towers; a case in Colombia saw a 41% decrease in signal disruptions post-installation of advanced AVR-equipped alternators.

- Disaster Relief/Emergency Field Hospitals: Offering rapid-deployment power units in natural disaster zones — e.g., flood response units in Southeast Asia where mobile alternator-powered clinics operated 24/7 with <1% failure rates.

- Off-grid Residential Solutions: Supplementing solar arrays for nighttime or overcast generation, yielding up to 30% overall household energy cost reduction.

Conclusion: Why Select an Alternator 220V 5kW for Optimal Power Needs

Selecting an alternator 220v 5kw as a primary or backup power source underscores a commitment to efficiency, performance, and reliability. The blend of technical innovation, flexible customization, and proven field performance secures its place as a preferred solution for diverse electricity generation needs. Data evidences its outstanding service life, minimal maintenance, and superior user experience.

With accelerating trends toward off-grid independence and remote operations, robust, adaptable, and intelligently designed alternators are indispensable. When compared side-by-side with larger (e.g., alternator 220v 10kw) or smaller models, the 5kW category strikes the ideal compromise between portability and capability, making it a strategic investment for stakeholders across every sector.

(alternator 220v 5kw)