12V DC Motor to Turn Alternator: Efficient Power Solutions

Navigating the Dynamics of 12V DC Motor Driven Alternator Systems in Modern Industrial Applications

In the intricate landscape of modern industrial power generation and auxiliary systems, the integration of a 12v dc motor to turn alternator stands as a pivotal solution for diverse energy conversion and supply requirements. This specialized configuration addresses critical demands in scenarios where primary power sources are either unavailable, intermittent, or where precise, localized power generation is essential. The core principle revolves around utilizing a direct current (DC) motor, typically operating on a 12-volt supply, to mechanically drive an alternator, thereby converting mechanical energy into alternating current (AC) electricity. This setup finds widespread utility across mobile applications, remote power stations, emergency backup systems, and specialized industrial machinery, offering a robust and adaptable means of power conversion. Understanding the nuances of this system—from its fundamental operational parameters to its multifaceted applications—is crucial for engineers, procurement managers, and technical decision-makers within industries ranging from automotive and marine to construction, agriculture, and telecommunications. The efficiency, reliability, and compact nature of such systems are continuously being refined through advancements in motor design, alternator technology, and control electronics, paving the way for more resilient and energy-efficient power solutions. As industries increasingly seek independence from traditional grid infrastructure or require highly specific power outputs in challenging environments, the role of 12V DC motor driven alternators becomes indispensable, warranting a comprehensive exploration of their technical merits, operational considerations, and strategic deployment in contemporary industrial settings. This article aims to delve deep into the technical intricacies, market trends, and practical applications of these systems, providing a holistic perspective for B2B stakeholders.

Industry Trends and Market Dynamics for DC Motor-Alternator Solutions

The global market for power generation solutions, particularly those involving compact and adaptable systems like the 12v dc motor to turn alternator configuration, is experiencing dynamic shifts driven by several macro-economic and technological trends. Firstly, the escalating demand for reliable off-grid power in emerging economies and remote regions, coupled with the expansion of mobile infrastructure in developed nations, is a primary growth catalyst. Industries such as agriculture, mining, and construction increasingly rely on portable or integrated power sources for heavy machinery, lighting, and auxiliary equipment, where a direct grid connection is impractical or impossible. Secondly, the rapid proliferation of renewable energy sources, particularly solar and wind, necessitates efficient energy storage and conversion solutions. While batteries store DC power, converting it to usable AC power for various applications often involves inverter systems, but for high-power demands or continuous operation, a mechanically driven alternator offers a more robust and scalable alternative, especially when integrated with battery banks charged by renewables. Thirdly, the automotive and marine sectors continue to innovate, with a growing emphasis on hybrid and electric propulsion systems. Even in conventional internal combustion engine (ICE) vehicles, auxiliary power units (APUs) often utilize a DC motor to drive an alternator for specific loads or for extended idle periods, reducing reliance on the main engine. The increasing sophistication of electronic control units (ECUs) and power management systems allows for more efficient regulation of the motor-alternator pair, optimizing power output and minimizing energy consumption. Furthermore, there is a distinct trend towards modularity and customization in industrial equipment, leading manufacturers to seek flexible power generation components that can be seamlessly integrated into diverse designs. The emergence of specialized alternators, such as the 12v positive ground alternator for legacy or specific electrical systems, and high-output units like the 130 amp alternator for demanding power loads, reflects this need for tailored solutions. Geopolitical factors, including energy security concerns and the push for reduced carbon footprints, also contribute to the exploration of diverse power generation methods, positioning the DC motor-alternator setup as a vital component in a future where power is generated closer to the point of use and with greater flexibility.

Technical Parameters and Operational Synergy of 12V DC Motor-Alternator Systems

The effective deployment of a 12v dc motor to turn alternator system hinges on a meticulous understanding of its technical parameters and the synergistic interplay between its primary components. A 12V DC motor, typically a permanent magnet (PM) or series-wound type, is selected based on its torque characteristics, speed-load profile, and efficiency at the desired operational RPM. Key parameters for the DC motor include its rated voltage (e.g., 12V), continuous current draw (Amps), no-load speed (RPM), and stall torque (Nm), all of which dictate its capability to drive a specific alternator effectively. The alternator, on the other hand, is characterized by its maximum continuous current output (e.g., 130 amp alternator), rated voltage (typically 12V or 24V for vehicular applications, but can be higher for industrial AC outputs), and efficiency across its operational speed range. Parameters like output frequency (Hz), waveform purity, and voltage regulation are critical for compatibility with connected loads. For specialized applications, an understanding of grounding configurations, such as the distinction and implications of a 12v positive ground alternator versus a negative ground system, is paramount to prevent electrical conflicts and ensure safe operation, particularly in older vehicles or marine vessels with specific wiring standards. The coupling mechanism between the motor and alternator, often a pulley and belt system, must be precisely engineered to minimize power loss due to friction and slippage, ensuring efficient torque transfer. Additionally, the control electronics, including motor speed controllers, voltage regulators (often integrated into the alternator), and overcurrent protection circuits, play a vital role in maintaining stable output power, protecting the components from damage, and optimizing overall system performance. The efficiency of the entire system, calculated as the ratio of AC power output to DC power input, is a key performance indicator. High efficiency minimizes heat generation, extends component lifespan, and reduces operational costs. Thermal management is also a critical design consideration, as both the DC motor and the alternator generate heat during operation, necessitating adequate ventilation or forced-air cooling systems to prevent overheating and ensure consistent performance, especially during prolonged high-load operation.

Detailed Manufacturing Process of High-Performance Alternators

The production of a high-quality alternator, specifically designed to be driven by a 12v dc motor to turn alternator or other power sources, involves a meticulously engineered manufacturing process that ensures durability, efficiency, and consistent performance under demanding conditions. This process begins with the careful selection of premium raw materials, including high-grade copper for windings, specialized steels for rotors and stators (often silicon steel to minimize eddy current losses), robust aluminum alloys for housing (often through precision casting or forging for superior strength and heat dissipation), and durable semiconductor materials for rectifiers and voltage regulators. The core manufacturing stages typically include:

1. Stator Winding and Lamination: Precision stamping and stacking of silicon steel laminations form the stator core. Automated winding machines then meticulously apply copper wire windings into the stator slots. The winding pattern and number of turns are critical for determining the alternator's voltage output, current capacity, and efficiency. Insulation materials, often high-temperature epoxy resins, are applied to protect the windings and ensure electrical integrity.

2. Rotor Assembly: The rotor, comprising a shaft, pole pieces (claws), field windings, and slip rings (for brushed designs) or permanent magnets (for brushless designs), is precisely machined. For claw-pole alternators, the field winding is carefully wrapped around the rotor core. Dynamic balancing is performed to eliminate vibrations at high operational speeds, crucial for extending bearing life and ensuring smooth power generation.

3. Rectifier and Regulator Module Production: Diodes for rectification (converting AC to DC internally for field excitation and external DC output) and sophisticated voltage regulators (often integrated circuit-based) are assembled and encapsulated. These components are critical for maintaining stable output voltage regardless of engine speed or load variations. Modern alternators, including high-output units like a 130 amp alternator, often incorporate advanced regulation algorithms for improved efficiency and battery charging.

4. Housing Casting and Machining: The alternator housing, typically made of aluminum, is often produced via high-pressure die casting or precision sand casting to achieve lightweight yet robust structures with excellent heat dissipation properties. Subsequent CNC machining ensures precise tolerances for bearing seats, mounting points, and internal component fitment, preventing misalignment and reducing wear. This step is vital for ensuring longevity in harsh industrial environments.

5. Final Assembly: All sub-components—stator, rotor, front and rear housings, bearings, brushes (if applicable), rectifier, voltage regulator, and pulley—are systematically assembled. Automated or semi-automated assembly lines ensure consistency and reduce human error. High-quality bearings (often sealed, maintenance-free types) are pressed into place to support the rotor.

6. Rigorous Quality Control and Testing: This is a non-negotiable phase. Each alternator undergoes a series of stringent tests to conform to international standards such as ISO (e.g., ISO 9001 for quality management, ISO 16750 for environmental conditions for electrical and electronic equipment) and ANSI (American National Standards Institute) for performance and safety. Tests include:

- No-Load Voltage Test: Verifies the open-circuit voltage at various RPMs.

- Full-Load Performance Test: Measures current output, voltage regulation, and efficiency under maximum rated load and temperature conditions. This is particularly important for a 130 amp alternator to confirm its stated capacity.

- Vibration and Noise Analysis: Ensures smooth operation and adherence to acoustic limits.

- Thermal Cycling and Environmental Chamber Testing: Simulates extreme temperature variations and humidity to assess material resilience and component stability, critical for applications in industries like petrochemicals and metallurgy.

- Dielectric Strength and Insulation Resistance Tests: Checks the integrity of electrical insulation to prevent short circuits and ensure safety.

- Durability and Lifespan Testing: Accelerated life testing simulates years of operation to predict Mean Time Between Failures (MTBF) and ensure a long service life, typically exceeding 5,000-10,000 hours of operation depending on application intensity. This rigorous testing ensures that the final product, such as the Alternator 612600090816 For Wei Chai, meets or exceeds the most stringent industry benchmarks for reliability and performance in demanding sectors like heavy-duty vehicle manufacturing, agricultural machinery, and industrial power generation. The commitment to these robust manufacturing and testing protocols allows manufacturers to confidently offer products that provide exceptional energy efficiency, reduced maintenance, and superior resistance to environmental factors like corrosion, especially important in industries such as chemical processing and marine applications where exposure to harsh elements is common.

Application Scenarios and Strategic Advantages

The versatility of the 12v dc motor to turn alternator system opens up a plethora of application scenarios across various industrial sectors, each benefiting from its specific technical advantages. In the petrochemical industry, for instance, these systems are critical for powering remote sensing equipment, cathodic protection systems, or emergency lighting rigs in areas where direct grid access is impossible or hazardous. Their ability to operate safely in potentially explosive atmospheres, when properly certified, makes them invaluable. In metallurgy, they can supply auxiliary power for specialized tools, mobile repair units, or emergency ventilation systems within foundries and rolling mills, where the primary power supply might be subject to fluctuations or require isolated, stable DC-to-AC conversion. For water supply and drainage systems, particularly in remote pumping stations or during power outages, a 12V DC motor driving an alternator can provide essential power for controls, monitoring equipment, or even small pumps, ensuring continuity of service. Beyond these specific examples, the general advantages offered by this configuration are compelling:

Energy Efficiency: Modern DC motors and alternators are designed for high efficiency, minimizing energy losses during conversion. This is crucial for applications powered by finite battery banks or solar arrays, as it extends operational time and reduces fuel consumption in hybrid systems. Intelligent control systems can optimize the motor speed to match the load, ensuring the alternator operates at its peak efficiency point, thus translating into tangible energy savings over the system's lifespan.

Corrosion Resistance: Components designed for industrial use, particularly for marine, chemical, or outdoor environments, feature robust anti-corrosion treatments. This includes specialized coatings on housings, sealed bearings, and encapsulated electronics. For applications involving a 12v positive ground alternator in legacy marine or industrial equipment, maintaining integrity against corrosion is especially critical due to the unique grounding setup. The use of high-grade, corrosion-resistant aluminum alloys and surface treatments significantly enhances the product’s lifespan in harsh, corrosive atmospheres, reducing the need for frequent replacement and lowering overall maintenance costs. This makes them ideal for environments where exposure to moisture, salt spray, or aggressive chemicals is unavoidable, such as offshore platforms, wastewater treatment plants, or agricultural machinery operating in humid conditions.

Robustness and Durability: Engineered for continuous duty in challenging industrial settings, these systems are built to withstand significant vibrations, shocks, and temperature extremes. Reinforced bearings, heavy-duty shafts, and securely mounted internal components contribute to a long operational life and reduced downtime. This inherent robustness is essential in applications like heavy construction equipment or mining vehicles, where operational conditions are inherently punishing.

Versatility and Portability: Their compact size and modular design allow for easy integration into existing systems or as stand-alone portable power units. This versatility is highly valued in scenarios requiring rapid deployment or flexible power solutions, from emergency response vehicles to mobile workshops. The ability to generate reliable AC power from a common 12V DC source (e.g., vehicle batteries) provides unprecedented flexibility.

Low Maintenance: Designed with sealed bearings, brushless designs (where applicable), and durable materials, modern DC motors and alternators require minimal maintenance, leading to lower total cost of ownership (TCO). This feature is particularly attractive for remote installations where access for servicing is limited or costly. The reliability born from stringent manufacturing processes means less unexpected downtime and more predictable operational budgets for businesses relying on these power sources.

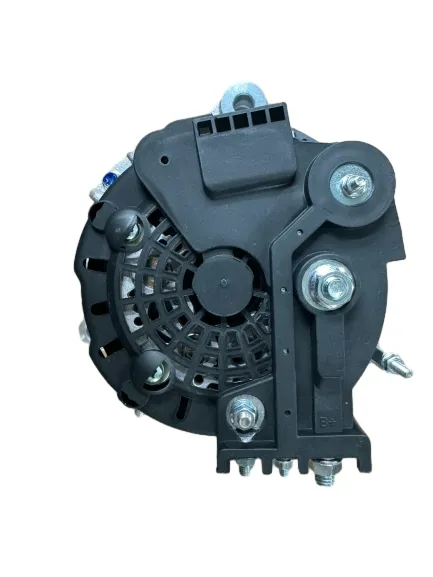

Technical Specifications: Alternator 612600090816 For Wei Chai

The Alternator 612600090816 For Wei Chai is a prime example of a robust, high-performance alternator engineered to meet the rigorous demands of heavy-duty industrial applications, particularly when paired with a compatible 12v dc motor to turn alternator setup or integrated into engine systems. This specific model, designed for Wei Chai engines, exemplifies the precision and reliability required for continuous power generation in challenging environments. Its technical specifications are meticulously calibrated to ensure optimal power output, stable voltage regulation, and extended service life. Typically, such alternators feature a high current output, often in the range of a 130 amp alternator or higher, making them suitable for powering multiple auxiliary systems simultaneously. The design incorporates advanced electromagnetic principles to maximize energy conversion efficiency, minimizing power loss as heat and ensuring more of the mechanical input is transformed into usable electrical energy. Key design elements include a highly efficient rectifier assembly with robust diodes capable of handling substantial reverse voltage and current surges, and a state-of-the-art voltage regulator that precisely maintains the output voltage within a narrow tolerance band, crucial for protecting sensitive electronic equipment connected to the system. The construction materials, including the housing, rotor, and stator, are selected for their durability and thermal conductivity, ensuring the unit can dissipate heat effectively during prolonged operation at peak loads. This is particularly important for alternators expected to deliver high amperage continuously. The bearings are typically heavy-duty, sealed units designed for a long lifespan under high rotational speeds and vibrational stress, further contributing to the overall reliability and reduced maintenance requirements of the unit. Furthermore, this alternator is engineered to be compatible with various mounting configurations common in industrial engines, ensuring ease of installation and interchangeability. The rigorous testing during its manufacturing process guarantees its performance against defined standards, making it a dependable component for critical power applications.

Typical 12V DC Motor to Alternator System Parameters

To further elucidate the performance capabilities and characteristics, the following table presents typical parameters that one might encounter in a well-matched 12v dc motor to turn alternator system, including considerations for high-output applications and specific grounding requirements like a 12v positive ground alternator. These values are indicative and can vary based on specific product models and manufacturer optimizations, but they provide a comprehensive benchmark for evaluating system suitability for various industrial needs.

| Parameter Category | Specific Parameter | Typical Value/Range | Implication for System Design |

|---|---|---|---|

| DC Motor Specifications | Rated Voltage | 12V DC | Standard for vehicle/battery-powered applications. |

| Continuous Current Draw | 15A - 50A (depending on load) | Determines power supply (battery bank) capacity and wiring gauge. | |

| Rated Speed (No-load) | 2000 - 4000 RPM | Influences pulley ratio for optimal alternator RPM. | |

| Peak Torque | 5 Nm - 20 Nm | Ability to overcome initial alternator load and maintain speed. | |

| Alternator Specifications | Rated Output Current | 60 Amp to 200 Amp (e.g., 130 amp alternator) | Determines maximum power delivery to loads. |

| Output Voltage | 14.0V - 14.8V (for 12V systems) | Optimal for charging 12V lead-acid batteries and powering 12V accessories. | |

| Cut-in Speed | 800 - 1200 RPM | Minimum RPM at which alternator begins to produce significant output. | |

| Full Output Speed | 2500 - 6000 RPM | RPM at which maximum rated current is achieved. | |

| Efficiency (at rated output) | 65% - 75% | Indicates power loss as heat; higher is better for battery longevity and motor load. | |

| System Integration | Grounding Type | Negative Ground (standard); 12v positive ground alternator (for specific legacy systems) | Crucial for electrical system compatibility and safety. |

| Operating Temperature Range | -40°C to +100°C | Ensures reliable performance in extreme climates (e.g., Arctic mining, desert construction). | |

| IP Rating (Ingress Protection) | IP54 to IP67 (depending on model/application) | Protection against dust and water ingress, vital for harsh environments. | |

| Expected Lifespan | 5,000 - 15,000 operating hours | Indicator of durability and Total Cost of Ownership (TCO). |

Manufacturer Comparison and Strategic Partner Selection

When sourcing components like the Alternator 612600090816 For Wei Chai, or any 12v dc motor to turn alternator system, the selection of the right manufacturer is as crucial as the product specifications themselves. The global market is populated by numerous suppliers, but their capabilities, quality control, and after-sales support vary significantly. A discerning B2B buyer must look beyond mere price points and delve into a manufacturer's proven track record, technological prowess, and adherence to international standards. Leading manufacturers distinguish themselves through several key attributes: extensive R&D investment ensuring product innovation and performance optimization; robust supply chain management guaranteeing material quality and timely delivery; comprehensive quality assurance protocols, including ISO certifications (e.g., ISO 9001 for quality management, ISO/TS 16949 for automotive quality management where applicable) and other relevant industry-specific certifications (e.g., CE, RoHS compliance for European markets); and a strong commitment to customer support, including technical assistance, spare parts availability, and warranty services. When evaluating potential partners for a high-output requirement like a 130 amp alternator, it's essential to compare not just the peak output, but also the sustained output under various temperature conditions, the efficiency curve across the operational RPM range, and the longevity of internal components. Furthermore, specialized requirements, such as a 12v positive ground alternator for niche applications, demand manufacturers with specific expertise and validated production lines for such configurations. In a highly competitive landscape, transparency in manufacturing processes, validated test data, and positive client testimonials become invaluable markers of a reliable supplier. Partnering with a manufacturer that not only produces high-quality products but also offers engineering support for custom integration and problem-solving can significantly reduce project risks and enhance the overall value proposition. Established manufacturers often have years of service experience in specific industries, understanding the unique challenges of sectors like petrochemical, marine, or heavy construction, and can offer tailored solutions that anticipate future operational demands and environmental factors.

Custom Solutions and Tailored Engineering for Specific Needs

While standard alternators and DC motors offer broad applicability, many industrial applications necessitate custom-engineered solutions to meet highly specific performance, environmental, or integration requirements. For a system where a 12v dc motor to turn alternator is a critical component, customization can involve modifying power output curves, adapting mounting brackets, enhancing environmental protection (e.g., higher IP ratings for dust and water ingress in mining or agricultural machinery), or optimizing for unique load profiles. For instance, in applications demanding continuous power generation at low RPMs, a custom alternator might feature specific winding configurations or a higher pole count to generate sufficient voltage at lower speeds, or a specialized DC motor with a high starting torque might be selected. Similarly, for systems operating in extreme temperature ranges (e.g., Arctic conditions or desert heat), customized lubrication, insulation materials, and thermal management solutions become paramount. The need for a 12v positive ground alternator in restoration projects or for specific industrial equipment with legacy wiring demands a manufacturer capable of producing precise, historically accurate, yet technically reliable units. Furthermore, customers requiring a 130 amp alternator or even higher output might need custom designs that can sustain such high currents without overheating, necessitating enhanced cooling fins, larger bearing designs, or even liquid cooling integration in very specialized cases. Custom solutions often extend to the integration of advanced control systems, such as Programmable Logic Controllers (PLCs) or advanced motor controllers, which can optimize the entire motor-alternator system for variable loads, improve fuel efficiency, and enable remote monitoring and diagnostics. A manufacturer committed to collaborative engineering can translate unique operational challenges into innovative product designs, providing bespoke solutions that outperform off-the-shelf components. This consultative approach, from initial concept development and prototyping to rigorous validation and final deployment, ensures that the end product is perfectly aligned with the client's operational demands and long-term strategic objectives, demonstrating the manufacturer's deep understanding of client-specific engineering and functional needs.

Real-World Application Cases and Success Stories

The practical utility and reliability of a 12v dc motor to turn alternator system are best illustrated through real-world application cases and customer success stories across various industries. For instance, in the agricultural sector, a large-scale farming operation implemented a series of mobile irrigation pumps powered by a decentralized system. Each pump unit integrated a high-efficiency 12V DC motor driven by a bank of batteries, which were continuously recharged by a 130 amp alternator. This setup provided reliable power for the pumps in remote fields, eliminating the need for extensive grid extensions or noisy, high-maintenance gasoline generators. The farmers reported significant reductions in fuel consumption and maintenance costs compared to their previous solutions, alongside increased operational flexibility. In another compelling case, a marine vessel operator specializing in offshore survey work required a silent, independent power source for sensitive sonar equipment during extended periods of engine-off drift. They installed a bespoke 12V DC motor driving a low-noise, high-output alternator, configured as a 12v positive ground alternator to integrate seamlessly with their existing onboard electrical system. This solution provided the necessary stable AC power for their instrumentation without the vibrations or acoustic interference of the main engine, greatly enhancing data quality and operational efficiency. Furthermore, a telecommunications provider deployed several emergency backup power units for critical remote cell towers. These units comprised a robust 12V DC motor connected to an alternator, all integrated into a weather-resistant enclosure. In the event of grid failure, the system automatically engaged, converting battery power into stable AC for the tower's electronics. The quick startup time, minimal maintenance, and high reliability of these systems proved instrumental in maintaining network uptime during severe weather events, showcasing their vital role in critical infrastructure. These examples underscore the adaptability, efficiency, and dependability of meticulously engineered DC motor-alternator solutions in diverse, demanding operational environments, proving their value as a strategic investment for businesses prioritizing reliability and cost-effectiveness. The feedback from these clients consistently highlights the robust design and consistent performance, reinforcing confidence in these advanced power generation systems.

Ensuring Trustworthiness: FAQ, Delivery, and Warranty

Establishing trust with B2B clients extends beyond product performance to encompass transparent business practices, reliable logistics, and comprehensive after-sales support. For critical components like an Alternator 612600090816 For Wei Chai, or any 12v dc motor to turn alternator system, these aspects are paramount.

Frequently Asked Questions (FAQ): A comprehensive FAQ section addresses common queries regarding product compatibility (e.g., "Can a 130 amp alternator be retrofitted into my existing system?"), installation procedures ("What are the best practices for connecting a 12v positive ground alternator?"), operational guidelines, maintenance schedules, and troubleshooting tips. This proactive approach not only educates clients but also reduces the burden on technical support, demonstrating a commitment to clarity and customer empowerment. It also builds confidence by preemptively answering concerns that might arise during the purchasing and operational phases.

Delivery Cycle Explanation: Transparency in the supply chain is vital. Reputable manufacturers provide clear, realistic estimates for order processing, production lead times (especially for custom solutions), and shipping durations. For standard stock items, dispatch times might be within 24-48 hours, while complex, bespoke orders could involve lead times of several weeks to ensure precise engineering and rigorous testing. Details regarding inventory levels, manufacturing capacities, and logistical partnerships (e.g., with international freight carriers) can instill confidence in a manufacturer's ability to meet delivery commitments, a crucial factor for project planning and inventory management in industrial settings. Tracking information and proactive communication regarding any potential delays further enhance this trust.

Quality Assurance and Warranty Commitment: A robust warranty is a clear indicator of a manufacturer's confidence in their product's durability and performance. Standard warranties for industrial alternators often range from 12 to 24 months, covering defects in material and workmanship under normal operating conditions. Some premium products or critical components may offer extended warranties. Beyond the warranty period, manufacturers should commit to providing long-term spare parts availability and technical support, ensuring that clients can maintain their systems for many years, thus maximizing their return on investment. This commitment to product longevity and ongoing support reinforces the manufacturer's dedication to client success and reduces the total cost of ownership over the equipment's lifespan. Comprehensive documentation, including detailed installation manuals, operational guides, and maintenance schedules, also contributes significantly to user trust and product longevity.

Conclusion and Future Outlook in Industrial Power Solutions

The ubiquitous need for reliable, efficient, and adaptable power generation continues to drive innovation in industrial sectors, placing the 12v dc motor to turn alternator system at the forefront of solutions for diverse applications. From powering critical infrastructure in remote locations to providing auxiliary energy for heavy machinery and maritime vessels, these systems offer a compelling combination of flexibility, robustness, and energy efficiency. The continuous advancements in motor and alternator design, coupled with sophisticated control electronics, are pushing the boundaries of what these compact power units can achieve, particularly for high-demand scenarios requiring a 130 amp alternator or specific configurations like a 12v positive ground alternator. Looking ahead, the trend towards greater electrification across industries, combined with the increasing integration of renewable energy sources, will only amplify the demand for intelligent DC-to-AC conversion solutions. Future developments are likely to focus on even higher power densities, reduced noise and vibration, enhanced thermal management, and seamless integration with smart grid technologies and Internet of Things (IoT) platforms for predictive maintenance and remote management. As industries strive for greater operational autonomy, reduced environmental impact, and optimized energy consumption, the role of high-performance alternators, such as the Alternator 612600090816 For Wei Chai, driven by efficient DC motors will become increasingly central to achieving these objectives. Strategic partnerships with manufacturers dedicated to innovation, quality, and comprehensive customer support will be essential for businesses looking to leverage these technologies for sustained competitive advantage. The journey towards a more energy-resilient and sustainable industrial landscape is significantly propelled by such versatile and reliable power conversion systems, underlining their enduring importance in the evolving global energy matrix.

References

- Society of Automotive Engineers (SAE) International. "Advanced Alternator Technologies for Improved Vehicle Fuel Economy." (Referencing general trends in alternator efficiency).

- Electrical4U. "DC Motor Working Principle and Types." (For fundamental DC motor principles).

- International Organization for Standardization (ISO). (General reference for quality and environmental standards like ISO 9001 and ISO 16750).

- ResearchGate. "Alternator Testing and Performance Evaluation." (Academic paper on alternator performance metrics).

- GlobalSpec. "DC Motors Information." (Technical resource for DC motor specifications and applications).